Best Practices For Maintaining Acoustic Wood Panels

Best practices for maintaining acoustic wood panels are essential for preserving both their aesthetic appeal and soundproofing capabilities. These panels play a crucial role in enhancing the acoustic quality of spaces, making their upkeep vital for long-term performance. By understanding proper maintenance procedures, you can ensure that your panels not only look great but also function effectively for years to come.

From routine cleaning techniques to moisture control strategies, this guide covers every aspect necessary for maintaining your acoustic wood panels. Neglecting maintenance can lead to unsightly damage and diminished performance, but with the right knowledge and tools, you can keep them in prime condition. Whether you’re a first-time user or have been enjoying the benefits of acoustic wood panels for years, these best practices will help you safeguard your investment.

Importance of Acoustic Wood Panels Maintenance

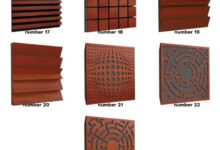

Acoustic wood panels serve a dual purpose in modern spaces—enhancing sound quality and elevating aesthetic appeal. Their ability to absorb sound waves makes them invaluable in environments such as recording studios, conference rooms, and even residential settings where noise control is essential. However, the beauty and functionality of these panels are directly linked to how well they are maintained over time.Maintaining acoustic wood panels is crucial not only for preserving their visual charm but also for ensuring optimal acoustic performance.

Regular upkeep can mitigate long-term wear and tear, allowing the panels to function effectively for years. Neglecting this maintenance can lead to numerous problems, including diminished sound absorption, visible damage, and even a decline in the overall ambiance of the space.

Role of Acoustic Wood Panels in Soundproofing and Aesthetics

The integration of acoustic wood panels into a space enhances both sound management and the interior design. These panels are designed to reduce echo and reverberation, creating an environment where conversations and music can be enjoyed without interference from disturbing background noises. Aesthetically, they offer a warm, natural look that complements various design themes—from contemporary to rustic.In terms of maintenance, it’s vital to keep the panels clean and free from dust and grime, as these can significantly impact their sound-absorbing properties.

For instance, a buildup of dirt can create a barrier that prevents sound waves from penetrating the wood, leading to a noticeable decline in acoustic effectiveness.

Long-term Benefits of Maintaining Acoustic Wood Panels

Investing time and effort in the maintenance of acoustic wood panels yields significant long-term benefits. Proper care ensures that the panels retain their sound-damping qualities, prolonging their lifespan and effectiveness. Here are some key advantages of regular maintenance:

- Enhanced Sound Quality: Regular cleaning and periodic inspections help maintain the panels’ acoustic properties.

- Extended Lifespan: Maintenance helps in identifying issues early, preventing costly repairs or replacements in the future.

- Preserved Aesthetic Appeal: Clean and well-maintained panels contribute to the overall beauty of the space, keeping it visually appealing.

Potential Issues from Neglecting Maintenance

Neglecting the maintenance of acoustic wood panels can lead to several issues that may compromise both functionality and appearance. Over time, dirt accumulation, moisture, and scratches can severely impact performance. The following points illustrate some common problems:

- Reduced Sound Absorption: Dirty surfaces cannot effectively absorb sound, leading to increased echo and noise levels.

- Physical Damage: Without proper care, panels can warp, crack, or lose their finish, necessitating costly repairs.

- Unpleasant Odors: Dust and moisture can lead to mold growth, resulting in musty smells that can affect indoor air quality.

Regular maintenance not only preserves the functionality of acoustic wood panels but also enhances the overall atmosphere of any given space.

When planning a beach getaway, discovering the complete amenities of five star hotels near beach is essential. These luxurious accommodations offer stunning ocean views, world-class dining, and exclusive spa treatments that elevate your experience. Whether you seek relaxation on the sand or vibrant nightlife, having access to top-tier facilities makes your stay truly unforgettable.

Cleaning Procedures for Acoustic Wood Panels

Maintaining the aesthetic and functional integrity of acoustic wood panels is essential for optimal performance. Regular cleaning not only enhances their visual appeal but also ensures effective sound absorption. The following cleaning procedures Artikel the best practices for safely cleaning and maintaining these valuable installations.To effectively clean acoustic wood panels, one must follow a systematic approach that minimizes the risk of damage.

It’s important to choose the right tools and cleaning products to preserve the texture and finish of the wood while maintaining its acoustic properties. Here’s a step-by-step guide to ensure a thorough and safe cleaning process.

Step-by-Step Cleaning Guide

Begin by gathering necessary tools and products that will assist in the cleaning process. The proper preparation ensures that the cleaning is efficient and does not harm the panels.

- Gather Supplies: Collect microfiber cloths, a soft-bristle brush, mild soap or a specialized wood cleaner, and a vacuum with a soft brush attachment. Avoid harsh chemicals or abrasive materials that can damage the finish.

- Dusting: Start by gently removing dust and debris using a soft-bristle brush or a microfiber cloth. Work from the top of the panels downwards to prevent dust from settling on already cleaned areas.

- Vacuuming: Use a vacuum cleaner equipped with a soft brush attachment to carefully remove any stubborn dust particles. Make sure to keep the attachment slightly above the surface to avoid scratching the wood.

- Spot Cleaning: For stains or marks, dampen a microfiber cloth with a solution of mild soap and water, then gently rub the affected area. Always test a small, inconspicuous area first to ensure no adverse reactions occur.

- Drying: After cleaning, use a dry microfiber cloth to wipe the surface, removing any moisture to prevent water damage. Ensure the area is well-ventilated to facilitate drying.

Recommended Cleaning Products and Tools

Choosing the right cleaning products is crucial for maintaining the durability and appearance of acoustic wood panels. Here are some well-regarded options that provide effective results without compromising the integrity of the panels.

“Using specialized wood cleaners ensures the preservation of the finish and texture.”

When planning a beach getaway, the choice of accommodation can greatly enhance your experience. Opting for a hotel that offers the complete amenities of five star hotels near beach ensures not only luxury but also convenient access to stunning ocean views and recreational activities. From top-notch dining options to relaxing spa services, these hotels provide everything you need for a perfect retreat by the shore.

- Mild Soap Solutions: A gentle mixture of dish soap and water can effectively clean without harming the surface.

- Wood-Safe Cleaners: Look for pH-balanced, non-toxic wood cleaners designed specifically for wooden surfaces.

- Microfiber Cloths: These are ideal for dusting and cleaning as they are soft, absorbent, and less likely to scratch the surface.

- Soft-Bristle Brushes: Utilize a soft-bristle brush to reach into crevices and remove trapped dust without causing damage.

Methods for Removing Dust and Debris

Effective dust and debris removal techniques are essential for preserving the acoustic properties and aesthetic appeal of wood panels. Regular maintenance prevents accumulation that can degrade both appearance and performance.Utilizing the following methods ensures thorough cleaning without risking damage to the wood finish:

“Regular maintenance prevents dust buildup, which can compromise sound absorption.”

- Gentle Wiping: Always wipe in the direction of the wood grain to avoid scratching the surface. Use light pressure to remove particles without damaging the finish.

- Compressed Air: For hard-to-reach areas, using a can of compressed air can help dislodge dust without direct contact.

- Regular Maintenance Schedule: Establish a cleaning routine, ideally every few months, to keep the panels in optimal condition. Frequent light cleanings are preferable to infrequent deep cleanings.

Moisture Control Techniques

Controlling moisture levels in spaces with acoustic wood panels is essential for preserving their integrity and functionality. High humidity can lead to various issues, including warping, mold growth, and sound absorption degradation, which can compromise the acoustic environment. Implementing effective moisture control strategies will not only prolong the lifespan of these panels but also enhance their performance.Moisture control is paramount because wood is a natural material that reacts to changes in humidity.

When the moisture content in the air rises, wood can absorb this moisture, leading to expansion and potential warping. This not only affects the aesthetic appeal of the panels but can also disrupt their acoustic properties. Consequently, maintaining optimal humidity levels is crucial for both the performance and the durability of acoustic wood panels.

Humidity Regulation Strategies

To ensure a stable environment for acoustic wood panels, implementing various moisture control strategies is necessary. Here are some essential techniques that can help regulate humidity levels effectively:

- Use dehumidifiers in spaces prone to high moisture levels. This will help to actively remove excess humidity from the air.

- Install HVAC systems with humidity control features to maintain consistent air quality and moisture levels.

- Monitor indoor humidity regularly using hygrometers to ensure levels remain within the ideal range of 30% to 50%.

- Seal windows and doors properly to prevent outside moisture from entering the space, particularly during rainy seasons.

- Ensure adequate ventilation in areas where moisture is likely to accumulate, such as kitchens and bathrooms, to facilitate air circulation.

Maintaining proper humidity levels can prevent significant damage to acoustic wood panels. Regular monitoring and the use of appropriate technologies create a stable environment conducive to preserving the quality and performance of these panels.

Checklist for Humidity Monitoring

Establishing a consistent monitoring routine is vital for maintaining appropriate humidity levels. Below is a checklist that Artikels key actions to ensure the environment remains favorable for acoustic wood panels:

- Check humidity levels daily using a hygrometer.

- Adjust the HVAC settings or dehumidifiers based on the readings obtained.

- Inspect for any signs of condensation or mold growth on the panels regularly.

- Ensure that all ventilation systems are functioning effectively and are not blocked.

- Review and update insulation in walls and ceilings to prevent moisture ingress.

Implementing these strategies and maintaining a thorough checklist will not only uphold the aesthetic and acoustic qualities of wood panels but also assure their longevity and effectiveness in any space.

Inspecting for Damage

Regular inspection of acoustic wood panels is crucial for maintaining their aesthetic appeal and functional integrity. These panels are designed to enhance sound quality and reduce noise, but over time they can experience wear and tear due to environmental factors, usage, and aging. Identifying damage early allows for timely repairs, ensuring the panels continue to perform optimally and look their best.Inspecting acoustic wood panels involves a systematic approach to identifying various types of damage.

Common issues include scratches, dents, discoloration, and moisture-related deterioration. These damages can stem from a variety of causes such as excessive moisture, physical impact, or inadequate maintenance. A thorough inspection process not only helps in recognizing these issues but also aids in documenting their conditions for future reference.

Types of Damage and Their Causes

Understanding the specific types of damage that can affect acoustic wood panels is essential for effective maintenance. The following list Artikels common types of damage and their potential causes:

- Scratches: Often caused by furniture movement, equipment placement, or contact with sharp objects. Regularly checking for scratches can prevent further deterioration.

- Dents: Resulting from heavy impacts, such as dropped tools or equipment. These can be minimized by ensuring a clear workspace around the panels.

- Discoloration: Frequently attributed to sunlight exposure or chemical cleaning agents. Protecting panels from direct sunlight and using appropriate cleaning solutions is vital.

- Moisture Damage: Occurs when panels are exposed to high humidity or leaks. Ensuring proper moisture control can prevent significant damage.

- Delamination: A more severe issue where layers of the panel separate, usually due to prolonged exposure to moisture or poor-quality adhesive. Immediate action should be taken to address this issue to avoid replacement.

To effectively document and address any damage found during inspections, consider the following tips:

- Maintain a Log: Create a detailed log that includes photographs and written descriptions of any damage identified. Regular updates will create a comprehensive history of the panels’ condition.

- Schedule Regular Inspections: Establish a routine inspection schedule, ideally every six months, to ensure any issues are caught early.

- Engage Professionals: For significant damages, consulting with a professional installer or restorer can provide solutions that ensure the longevity of the panels.

- Develop a Repair Plan: Based on the inspection findings, Artikel a clear plan for addressing damages, prioritizing repairs based on severity and potential impact on performance.

Regular inspections of acoustic wood panels are key to maintaining their aesthetic and functional integrity.

Repair Methods for Acoustic Wood Panels: Best Practices For Maintaining Acoustic Wood Panels

Maintaining the aesthetic and functional integrity of acoustic wood panels is vital for optimizing sound quality and visual appeal. Over time, these panels may endure minor scratches and dents due to regular wear and tear. Understanding effective repair methods can help to prolong their lifespan and maintain their acoustic properties.

Repair Techniques for Minor Scratches and Dents

Minor scratches and dents can be addressed with various techniques that offer a quick fix without the need for professional intervention. These methods can restore the surface and maintain the panel’s appearance:

- Wood Filler: For shallow scratches, applying a color-matched wood filler can effectively conceal imperfections. Once dried, sanding lightly improves the surface finish.

- Touch-Up Markers: Utilizing a wood touch-up marker can be an efficient way to mask small scratches. Choose a marker that closely matches the panel’s finish for best results.

- Steam Treatment: A steam iron can help raise the wood fibers in shallow dents. By applying moisture and heat, the dent can often be diminished without leaving a trace.

Addressing Significant Damage or Panel Replacement

When dealing with substantial damage, the repair process requires a more methodical approach. It is essential to evaluate the extent of the damage and determine whether repair or replacement is the best option:

- Panel Replacement: If the panel is severely damaged, replacing the entire panel may be necessary. Ensure the new panel matches the existing ones in both acoustical properties and finish.

- Re-veneering: This technique involves replacing the outer layer of wood, providing a fresh look while preserving the underlying structure. This is a viable option for panels with aesthetic damage.

- Structural Reinforcement: In some cases, internal damage may compromise panel integrity. Reinforcing the frame or using additional supports can restore functionality.

Comparing DIY Repair Options and Professional Services

Choosing between DIY repair methods and hiring professionals depends on various factors, including the severity of the damage and the desired outcome. Each approach has its advantages and considerations:

- DIY Repair: Cost-effective and time-efficient, DIY methods empower owners to maintain their panels without significant investment. Many minor repairs can be accomplished with basic tools and materials.

- Hiring Professionals: For complex repairs or when ensuring the highest quality finish is paramount, professional services can guarantee results. Experts have the experience and specialized tools necessary for intricate repair tasks.

- Cost Consideration: Weighing the costs of professional repairs against the potential for DIY mistakes is essential. Minor repairs may be manageable, while extensive damage might warrant expert assistance.

Maintaining the integrity of acoustic wood panels not only enhances their aesthetic appeal but also ensures optimal sound performance over time.

Environmental Factors Impacting Acoustic Wood Panels

Environmental factors play a critical role in the longevity and performance of acoustic wood panels. Understanding how elements such as sunlight exposure, temperature fluctuations, and moisture levels affect these panels can help in preserving their integrity and acoustic effectiveness. This section delves into the various environmental influences that can compromise the quality of acoustic wood panels and provides practical measures to mitigate these effects.

Effects of Sunlight Exposure on Acoustic Wood Panels

Sunlight exposure can significantly alter the appearance and performance of acoustic wood panels. Prolonged UV exposure leads to fading and discoloration, affecting not just aesthetics but also the physical properties of the wood. The ultraviolet rays can degrade the surface finish, resulting in a reduction in acoustic efficiency over time. To combat this, it is crucial to implement protective measures.

- Utilize window treatments such as blinds or UV-filtering films to minimize direct sunlight on panels.

- Apply protective coatings that resist UV damage and enhance the panel’s lifespan.

- Position acoustic panels strategically to avoid direct sunlight where feasible, especially in areas with high sun exposure.

Impact of Temperature Fluctuations on Wood Integrity

Temperature fluctuations can cause wood to expand and contract, which may lead to warping or cracking of acoustic panels. Stability in temperature is essential for maintaining the structural integrity of wood, as extreme changes can create stress within the material. In environments with significant temperature variance, the risk of damage increases, potentially undermining the acoustic performance of the panels.

- Maintain a consistent indoor temperature by using climate control systems and ensuring proper insulation.

- Regular monitoring of room temperature and humidity levels can help mitigate extremes.

- Consider using thermal insulation behind acoustic panels to buffer against temperature changes.

Best Practices for Protecting Panels from Environmental Elements

Protecting acoustic wood panels from adverse environmental conditions is vital for their longevity. Implementing best practices can significantly reduce the wear and tear caused by exposure to elements. Establishing a routine inspection and maintenance schedule ensures that potential issues are identified early.

- Regularly inspect panels for signs of damage, such as cracks or discoloration, and address issues promptly.

- Use dehumidifiers in areas with high moisture content to prevent mold and decay.

- Ensure adequate ventilation in spaces where acoustic panels are installed to promote air circulation and reduce moisture buildup.

Coating and Finishing Options

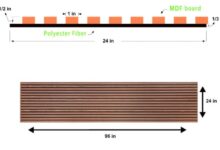

Protective finishes applied to acoustic wood panels play a crucial role in enhancing their durability and aesthetic appeal while ensuring optimal acoustic performance. These finishes not only shield the wood from environmental factors but also contribute to the overall longevity of the panels, making them a worthwhile investment for any space focused on sound quality. Different coatings can have varying effects on the acoustics of the panels, influencing sound absorption and reflection.

Benefits of Protective Finishes

Applying protective finishes to acoustic wood panels provides a variety of advantages. These include:

- Enhanced Durability: Finishes create a barrier against wear and tear, extending the life of the panels significantly.

- Moisture Resistance: Properly finished panels are less susceptible to water damage, which can compromise both the wood and its acoustic properties.

- Aesthetic Appeal: Finishes can enhance the natural beauty of the wood, allowing for a variety of aesthetic options that fit different design styles.

- Ease of Maintenance: Finished surfaces are easier to clean and maintain, ensuring that the panels remain in optimal condition over time.

Comparison of Coating Types

Different types of coatings can significantly affect the acoustics of wood panels. Here’s a brief comparison:

- Varnish: Provides a hard protective layer that enhances durability but may dampen sound absorption due to its density. Ideal for high-traffic areas where durability is paramount.

- Oil: Penetrates the wood, preserving its natural characteristics and allowing for better sound absorption, making it a preferred choice for spaces where acoustics are critical.

- Polyurethane: Offers a strong, water-resistant finish that is easy to clean, though it can alter the acoustic properties substantially, depending on its thickness.

Guide for Selecting and Applying Finishes

Choosing the right finish and applying it correctly is essential for maximizing the longevity and performance of acoustic wood panels. Consider the following steps:

- Assess the Environment: Determine the humidity and temperature conditions of the area where the panels will be installed to select a compatible finish.

- Select the Finish: Choose between varnish, oil, or polyurethane based on desired durability, aesthetics, and acoustic characteristics.

- Preparation: Ensure the panels are clean and dry. Sand the surface lightly to improve finish adhesion.

- Application: Apply the selected finish using a brush or spray, maintaining even coverage. Allow adequate drying time between coats to achieve the desired finish.

- Final Touches: After the final coat has dried, inspect the surface for consistency and apply additional coats if necessary for enhanced protection.

“Choosing the right finish is key to preserving both the beauty and functionality of acoustic wood panels.”

By following these guidelines, you can ensure that your acoustic wood panels remain not only visually appealing but also functionally effective in controlling sound.

Storage and Handling Guidelines

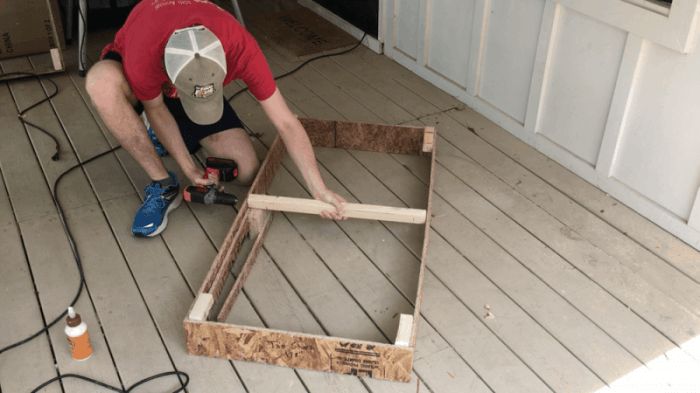

Proper storage and handling of acoustic wood panels is critical to ensure their longevity and performance. These panels are not only functional in sound absorption but also add aesthetic value to spaces. Following specific guidelines for storage, handling, and transportation can prevent damage and maintain their quality before installation and during maintenance.Acoustic wood panels should be stored in a controlled environment to protect them from moisture, temperature fluctuations, and physical impact.

When handling these panels, it is essential to follow best practices to avoid any scratches, dents, or warping.

Storage Methods for Acoustic Wood Panels

Storing acoustic wood panels correctly is essential for maintaining their integrity. Here are some effective strategies for storage:

- Store panels in a dry, climate-controlled area where temperatures remain stable to prevent warping.

- Keep panels flat and stacked on a level surface, using spacers to allow airflow between them. This prevents moisture accumulation.

- Cover panels with a breathable fabric to shield them from dust while allowing air circulation.

Handling Tips During Installation

Handling acoustic wood panels carefully during installation minimizes the risk of damage. Implement the following best practices:

- Always lift panels from the bottom, using two hands, to distribute weight evenly and avoid bending.

- Wear clean gloves to prevent oils and dirt from transferring onto the panels, which can affect their finish.

- Use soft, padded tools for installation to prevent scratches or dents on the surface of the panels.

Best Practices for Transporting Panels, Best practices for maintaining acoustic wood panels

Transporting acoustic wood panels requires attention to detail to ensure they remain undamaged. Consider these guidelines:

- Use a suitable vehicle that can accommodate the size of the panels without bending or putting pressure on them.

- Secure panels with straps or padding to prevent movement during transit, reducing the risk of chipping or scratching.

- Transport panels upright rather than flat, if possible, to reduce the risk of warping and damage from weight.

“Proper handling and storage are key to prolonging the life of acoustic wood panels, ensuring they perform their sound absorption function effectively.”

Final Review

In summary, maintaining acoustic wood panels is not just a task; it’s a commitment to enhancing your environment. By implementing the Artikeld best practices, from cleaning and moisture control to inspections and repairs, you can extend the life of your panels and maintain their effectiveness. Remember, a little effort goes a long way in preserving both the beauty and functionality of your acoustic wood panels, ensuring they continue to provide a harmonious atmosphere for all who enter the space.