Siding Material Comparison A Comprehensive Guide

Siding Material Comparison: Choosing the right siding can dramatically impact your home’s curb appeal, energy efficiency, and long-term value. This isn’t just about picking a color; it’s about understanding the nuances of different materials – their durability, maintenance needs, and overall cost-effectiveness. We’ll delve into the specifics of popular siding options, helping you make an informed decision that perfectly suits your needs and budget.

Get ready to unlock the secrets to siding success!

From the initial investment to long-term maintenance, the choice of siding material significantly affects your home’s overall performance and aesthetic. This guide provides a detailed comparison of various siding options, considering factors like durability, energy efficiency, cost, and environmental impact. We’ll explore the pros and cons of each material, equipping you with the knowledge to make a confident and well-informed decision for your project.

Introduction to Siding Materials

Choosing the right siding for your home is a crucial decision, impacting both its aesthetic appeal and long-term durability. The market offers a diverse range of materials, each with its own set of advantages and disadvantages. Understanding these differences is key to making an informed choice that aligns with your budget and desired outcome. This section will delve into the characteristics of common siding materials, providing a foundation for your selection process.

Several factors influence siding selection, including climate, architectural style, and budget. Durability, measured by lifespan and resistance to weather damage, is paramount. Aesthetics, encompassing color, texture, and overall visual appeal, are equally important for achieving the desired curb appeal. Finally, cost, encompassing initial purchase price, installation expenses, and long-term maintenance, plays a significant role in the decision-making process.

Common Siding Materials and Their Characteristics

This section details the properties of several popular siding materials. We’ll examine their durability, aesthetic qualities, and cost-effectiveness to aid in your decision.

Vinyl Siding: Vinyl is a popular choice due to its affordability and low maintenance. It’s resistant to rot, insects, and moisture, making it a durable option in many climates. However, it can be susceptible to damage from impact and extreme temperatures, and its aesthetic versatility is somewhat limited compared to other materials. Its lifespan typically ranges from 20 to 40 years, depending on quality and exposure.

Fiber Cement Siding: Fiber cement combines cement, cellulose fibers, and other additives to create a durable and fire-resistant siding option. It offers excellent protection against moisture, insects, and fire, boasting a longer lifespan than vinyl. Aesthetically, it mimics the look of wood, offering a range of textures and colors. However, it’s more expensive than vinyl and requires professional installation.

Wood Siding: Natural wood siding offers unparalleled aesthetic appeal, with a variety of grains, colors, and textures. However, it requires significant maintenance to prevent rot, insect infestation, and weathering. Its lifespan can vary greatly depending on the type of wood and the level of maintenance, ranging from 20 to 50 years or more for properly maintained cedar or redwood.

Metal Siding: Metal siding, typically aluminum or steel, is extremely durable and resistant to fire, insects, and moisture. It’s low-maintenance and boasts a long lifespan. While it’s more expensive than vinyl, its durability and longevity can offset the higher initial cost. However, it can dent and scratch easily, and it may not be aesthetically appealing to everyone.

Brick Siding: Brick is a classic and durable siding choice known for its exceptional longevity and resistance to weather damage. It’s fire-resistant and requires minimal maintenance. However, it is significantly more expensive than other options and can be more challenging to install. The lifespan of brick siding can exceed 100 years.

Siding Material Lifespan Comparison

The table below provides a general comparison of the lifespan of various siding materials. It’s crucial to remember that these are estimates, and actual lifespan can vary based on factors such as climate, installation quality, and maintenance.

| Siding Material | Typical Lifespan (Years) | Factors Affecting Lifespan | Maintenance Requirements |

|---|---|---|---|

| Vinyl | 20-40 | Quality, UV exposure, impact damage | Low |

| Fiber Cement | 30-50 | Climate, installation, maintenance | Moderate |

| Wood | 20-50+ | Wood type, climate, maintenance | High |

| Metal | 40-75+ | Material quality, exposure | Low |

| Brick | 100+ | Installation quality, weather exposure | Very Low |

Material Properties and Performance

Choosing the right siding material is a crucial decision impacting your home’s aesthetics, longevity, and energy efficiency. Understanding the material properties and performance characteristics is key to making an informed choice. This section dives into the thermal performance, moisture resistance, and maintenance needs of various siding options, helping you weigh the pros and cons effectively.

Thermal Performance and Energy Efficiency

The thermal performance of siding directly affects your home’s energy efficiency. Materials with high R-values (a measure of thermal resistance) provide better insulation, reducing heat transfer in both summer and winter. This translates to lower energy bills and a more comfortable living environment. For example, fiber cement siding generally boasts a higher R-value than vinyl, leading to potential savings on heating and cooling costs.

Conversely, materials with lower R-values, such as aluminum, may require more energy to maintain a stable indoor temperature. The difference can be significant, especially in climates with extreme temperature fluctuations. Consider the climate you live in when assessing the thermal performance of different siding materials; a high R-value is especially beneficial in regions with harsh winters or scorching summers.

Moisture Resistance and Susceptibility to Damage

Moisture is the enemy of most siding materials. Prolonged exposure to water can lead to rot, warping, cracking, and the growth of mold and mildew. The resistance to moisture varies significantly across different materials. Wood siding, while aesthetically pleasing, requires regular maintenance and protective coatings to withstand moisture. Vinyl siding, on the other hand, is generally highly resistant to moisture damage, requiring minimal upkeep.

Fiber cement siding also offers good moisture resistance but may require sealing in certain climates. Understanding the moisture resistance of your chosen siding is crucial for ensuring its longevity and preventing costly repairs. Think about the climate and your home’s exposure to rain, snow, and humidity when making your decision. A home located in a particularly humid region might benefit from a material with superior moisture resistance.

Maintenance Requirements

Maintenance needs vary considerably depending on the siding material. Vinyl siding is famously low-maintenance, often requiring only occasional cleaning with soap and water. Wood siding, however, demands more attention. It may need periodic repainting or staining to protect it from the elements and maintain its aesthetic appeal. Regular cleaning and inspections are also essential to catch and address any signs of damage early on.

Fiber cement siding typically requires less maintenance than wood but might need occasional cleaning and repainting, depending on the finish and exposure to the elements. Aluminum siding is relatively low-maintenance but can be susceptible to dents and scratches. Regular inspections and prompt repairs can help extend the lifespan of any siding material, regardless of its inherent durability. Consider your lifestyle and willingness to dedicate time to maintenance when choosing your siding.

A low-maintenance option may be ideal for busy homeowners who prefer to minimize upkeep.

Cost Analysis and Life Cycle Assessment

Choosing the right siding isn’t just about aesthetics; it’s a significant financial decision impacting your home’s value and your wallet for years to come. Understanding the initial costs, ongoing maintenance, and eventual replacement expenses is crucial for making an informed choice. This section delves into a comprehensive cost analysis and life cycle assessment of various siding materials, helping you determine which option offers the best return on investment for your specific situation.

The total cost of siding goes far beyond the initial purchase price. Factors like installation complexity, material lifespan, and required maintenance all contribute to the overall long-term expense. By carefully weighing these factors, you can avoid costly surprises down the road and select a siding that aligns with your budget and long-term goals.

Siding Material Cost Comparison

The following table provides a comparative analysis of the initial cost, installation cost, and projected long-term maintenance expenses for several common siding materials. Remember that these figures are estimates and can vary significantly based on factors such as location, labor rates, and material quality. Always obtain multiple quotes from reputable contractors before making a final decision.

| Siding Material | Initial Cost (per sq ft) | Installation Cost (per sq ft) | Annual Maintenance Cost (per sq ft) |

|---|---|---|---|

| Vinyl | $2-$5 | $3-$6 | $0.10-$0.25 |

| Fiber Cement | $6-$12 | $6-$10 | $0.25-$0.50 |

| Wood | $8-$20+ | $8-$15+ | $0.50-$2.00+ |

| Aluminum | $4-$8 | $5-$9 | $0.10-$0.30 |

Cost-Effectiveness Scenarios

While initial cost is a significant factor, long-term cost-effectiveness often dictates the best choice. Let’s explore some scenarios where specific siding materials shine.

For instance, vinyl siding offers a lower upfront cost and minimal maintenance, making it a budget-friendly option for homeowners prioritizing affordability. However, its shorter lifespan compared to fiber cement might lead to higher replacement costs over the long run. Conversely, fiber cement, despite a higher initial investment, boasts exceptional durability and longevity, potentially saving money on repairs and replacements over its lifetime.

This makes it a cost-effective choice for those seeking a long-term solution.

Wood siding, while aesthetically pleasing, demands significant upkeep, including regular painting or staining, which adds to the long-term expenses. This high maintenance makes it a less cost-effective choice for budget-conscious homeowners unless regular maintenance is prioritized.

Return on Investment (ROI) for Siding

Calculating the ROI for siding involves comparing the total cost (initial cost + installation + maintenance + eventual replacement) against the increase in home value and the savings on energy costs (some siding materials offer better insulation). A higher ROI indicates a more financially sound investment.

For example, a homeowner investing in energy-efficient fiber cement siding might see a higher ROI compared to someone opting for cheaper vinyl siding, due to reduced energy bills and increased property value. The increased property value resulting from the superior aesthetic appeal and longevity of the fiber cement siding contributes significantly to a strong ROI. Conversely, while vinyl offers a quick payback on the initial investment, the shorter lifespan could negatively impact the overall ROI in the long run.

Careful consideration of these factors is crucial for making a well-informed decision.

Aesthetics and Design Considerations: Siding Material Comparison

Choosing the right siding isn’t just about durability and cost; it’s a crucial design decision that significantly impacts your home’s curb appeal and overall aesthetic. The visual impact of siding can dramatically alter the perceived value and style of your property, influencing everything from its perceived age to its architectural harmony with the surrounding neighborhood. Let’s delve into how different siding materials offer unique aesthetic possibilities.

The interplay of material, color, and texture creates a powerful visual statement. Understanding these elements allows you to select a siding that perfectly complements your architectural style and personal preferences, enhancing the beauty and value of your home. Think of it as the clothing for your house – the right choice makes all the difference.

Siding Material Aesthetics and Architectural Styles

Different siding materials naturally lend themselves to specific architectural styles. For instance, the clean lines and modern feel of fiber cement siding often grace contemporary homes, while the rustic charm of wood siding is a perfect match for traditional or craftsman-style houses. The rich, deep tones and varied textures of stone or brick siding are frequently used in stately homes or those with a historical or European influence.

Vinyl siding, with its versatility, can adapt to various styles, although it might not be the first choice for those seeking a high-end, luxury look. Consider the overall architectural details of your home – intricate trim, large windows, or a simple, boxy design – to determine which siding will complement these features most effectively. A mismatch can create a jarring effect, detracting from the home’s overall appeal.

Color and Texture Choices in Siding

Color selection is paramount. A light-colored siding can make a home appear larger and brighter, especially in areas with limited sunlight. Conversely, darker colors can create a more dramatic and imposing look, suitable for larger homes or those seeking a bolder statement. However, remember that darker colors absorb more heat, potentially increasing cooling costs. Texture plays a crucial role too.

Smooth siding offers a clean, minimalist aesthetic, while textured siding adds depth and visual interest, often mimicking the appearance of natural materials like wood or stone. The interplay of color and texture can transform the look of a building; for example, a warm, earthy tone with a rough texture can evoke a rustic feel, while a cool gray with a smooth finish might convey a contemporary vibe.

Imagine a Victorian home clad in dark gray, textured vinyl siding – it simply wouldn’t match the delicate detailing and architectural style. Contrastingly, a sleek, modern home might benefit from the clean lines and subtle texture of a light gray fiber cement siding.

Examples of Siding Material Applications

Let’s consider a few examples to solidify these concepts. A craftsman-style bungalow might be beautifully complemented by cedar wood siding in a warm brown tone, emphasizing the natural elements of the design. The natural variations in wood grain add textural depth. Conversely, a contemporary, minimalist home might showcase the clean lines of fiber cement siding in a crisp white or light gray, reflecting its modern aesthetic.

The smooth surface of the fiber cement complements the sleek design. A Mediterranean-style villa could benefit from stucco siding in a warm terracotta color, enhancing its traditional, sun-drenched character. The textured surface of stucco evokes the feel of a traditional, hand-applied finish. These examples highlight how the careful selection of siding material, color, and texture can significantly enhance the architectural style and overall aesthetic of a building.

Environmental Impact

Choosing siding isn’t just about aesthetics and durability; it’s about the planet’s well-being too. The environmental footprint of your siding choice extends far beyond its initial purchase, encompassing manufacturing, transportation, and eventual disposal. Understanding these impacts is crucial for making an informed, eco-conscious decision. Let’s delve into the environmental considerations surrounding various siding materials.The manufacturing process for each siding material significantly influences its environmental impact.

For instance, vinyl siding production is energy-intensive and relies heavily on fossil fuels, contributing to greenhouse gas emissions. Conversely, wood siding, while a renewable resource, can have a considerable impact depending on its sourcing and processing. Sustainable forestry practices are vital to minimize the environmental footprint of wood siding. Similarly, the transportation of siding materials from manufacturing plants to distribution centers and ultimately to construction sites generates carbon emissions, further impacting the environment.

The heavier the material, and the longer the distance it travels, the greater the environmental burden. Finally, disposal poses a challenge. Many siding materials are not easily recyclable, leading to landfill accumulation.

Manufacturing Processes and Emissions

The environmental impact of siding manufacturing varies greatly depending on the material. Vinyl siding, a popular choice due to its affordability and low maintenance, has a relatively high carbon footprint due to its reliance on petroleum-based plastics and energy-intensive manufacturing processes. This contrasts sharply with fiber cement siding, which often utilizes recycled materials and requires less energy to produce.

Wood siding, sourced responsibly from sustainably managed forests, can offer a lower carbon footprint compared to vinyl, particularly if certified by organizations like the Forest Stewardship Council (FSC). However, the processing of wood, including cutting, drying, and treating, still contributes to energy consumption and emissions. Metal siding, such as aluminum or steel, has a higher upfront embodied carbon due to the energy-intensive smelting process, but its longevity and potential for recycling can mitigate this over its lifespan.

You also can investigate more thoroughly about Insulated Siding for Better Insulation to enhance your awareness in the field of Insulated Siding for Better Insulation.

Recycled Materials and Sustainable Sourcing

Increasingly, manufacturers are incorporating recycled materials into siding production to lessen their environmental impact. Some fiber cement siding products, for example, utilize fly ash and other industrial byproducts, diverting waste from landfills and reducing the need for virgin materials. Similarly, some manufacturers are focusing on sustainable sourcing of wood, ensuring that timber comes from responsibly managed forests certified by organizations like the FSC.

This certification guarantees that the wood is harvested in a way that protects biodiversity and minimizes environmental damage. The use of recycled aluminum in metal siding is also becoming more prevalent, reducing the demand for newly mined aluminum ore. Choosing siding products made with recycled content is a direct way to reduce the overall environmental impact of your project.

Embodied Carbon in Siding Materials

Embodied carbon refers to the greenhouse gas emissions associated with the entire life cycle of a material, from raw material extraction to manufacturing, transportation, and disposal. Different siding materials have vastly different embodied carbon footprints. Vinyl siding, due to its petroleum-based nature and manufacturing processes, generally has a higher embodied carbon than wood siding from responsibly managed forests.

Fiber cement siding, with its use of recycled materials and lower energy requirements, often exhibits a lower embodied carbon footprint. The embodied carbon of metal siding is significant upfront but can be offset by its longevity and recyclability. Accurate figures for embodied carbon vary depending on the specific product, manufacturing process, and transportation distance; however, life cycle assessments (LCAs) can provide valuable comparative data for informed decision-making.

For example, a LCA might show that while the initial embodied carbon of fiber cement is lower than vinyl, the longer lifespan of vinyl could mean that its overall carbon footprint is lower over a 50-year period. This illustrates the complexity of making direct comparisons.

Installation Methods and Techniques

Choosing the right siding material is only half the battle. Proper installation is crucial for ensuring longevity, performance, and maintaining the aesthetic appeal of your home’s exterior. Different siding materials demand unique installation techniques, impacting both the complexity and the time investment required. Let’s delve into the specifics of installing three popular siding options: vinyl, wood, and fiber cement.

Vinyl Siding Installation

Vinyl siding installation is generally considered a relatively straightforward process, even for DIY enthusiasts with some basic construction skills. The interlocking nature of the panels simplifies the process, allowing for quick and efficient coverage of large areas. However, meticulous attention to detail is still required to ensure a professional-looking, weathertight finish. Proper preparation of the underlying wall surface is paramount; any imperfections could show through the finished siding.

- Preparation involves cleaning the wall, ensuring it’s plumb and level, and installing starter strips and J-channels.

- Panels are then installed horizontally, overlapping each other and securing them with nails or clips.

- Finishing involves installing corner trims, window and door casings, and other necessary trim pieces.

Tools and equipment typically needed include a measuring tape, level, saw, hammer or nail gun, utility knife, and various trim pieces. Accurate cutting is essential to avoid gaps or misalignments. Improper installation can lead to issues such as water penetration, warping, and a generally unprofessional appearance. A well-installed vinyl siding system, however, can last for decades with minimal maintenance.

Wood Siding Installation, Siding Material Comparison

Wood siding offers a classic and aesthetically pleasing look, but its installation is more complex and time-consuming than vinyl. Wood is a natural material and requires careful handling to prevent damage and ensure a long lifespan. Proper sealing and painting are also crucial to protect the wood from moisture damage and insect infestation. The installation process often requires more precision and craftsmanship than vinyl siding.

The need for precise cuts and careful alignment makes this a more demanding project.

- Preparation includes framing and sheathing the wall, applying housewrap for moisture protection, and installing furring strips for proper ventilation.

- Wood siding boards are typically installed vertically or horizontally, depending on the style and design, and are often nailed or screwed into place.

- Finishing involves installing trim, caulking joints, and applying a protective sealant or paint.

Essential tools include a circular saw, miter saw, nail gun or hammer, level, measuring tape, and various woodworking tools for precise cuts and shaping. The quality of the wood and the skill of the installer significantly impact the final result and the longevity of the siding. Ignoring proper preparation or using low-quality materials will drastically reduce the lifespan and increase the likelihood of maintenance issues.

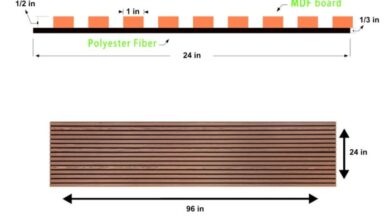

Fiber Cement Siding Installation

Fiber cement siding provides excellent durability and fire resistance but presents a more challenging installation process compared to vinyl. The panels are heavier and less forgiving than vinyl, demanding more precise cuts and careful handling. Specialized tools and safety precautions are often required due to the material’s density and the potential for breakage. The process requires a higher level of skill and experience.

- Preparation is similar to wood siding, requiring a properly prepared wall surface with appropriate sheathing and moisture barrier.

- Panels are usually installed vertically or horizontally, depending on the chosen design, and secured with nails or screws.

- Finishing involves installing trim, caulking joints, and ensuring proper flashing around windows and doors.

Necessary tools and equipment include a circular saw with a carbide-tipped blade (specifically designed for fiber cement), a level, measuring tape, safety glasses, and a dust mask. The heavier weight of the panels requires more robust fastening and careful handling to avoid damage during installation. Proper installation of fiber cement siding can result in a very durable and low-maintenance exterior, but improper installation can lead to costly repairs.

Maintenance and Repair

Proper siding maintenance is crucial for preserving its aesthetic appeal and extending its lifespan. Neglecting upkeep can lead to costly repairs down the line, impacting both your home’s value and your wallet. This section details cleaning, repair techniques, and preventative measures for various siding materials, helping you keep your home looking its best for years to come.

Cleaning and Maintaining Different Siding Materials

Regular cleaning removes dirt, grime, and mildew, preventing damage and maintaining your siding’s appearance. The frequency of cleaning depends on factors like climate and tree cover, but at least an annual cleaning is recommended. Different materials require slightly different approaches.

- Vinyl Siding: A simple wash with a garden hose and a mild detergent solution is usually sufficient. For stubborn stains, a soft-bristled brush can be used. Avoid harsh chemicals or high-pressure washers, as these can damage the siding’s surface.

- Wood Siding: Wood siding requires more attention. Regularly inspect for signs of rot, insect infestation, or damage. Cleaning involves using a pressure washer (low pressure setting) with a suitable wood cleaner. Follow up with a protective sealant to prevent water damage.

- Fiber Cement Siding: Fiber cement is relatively low-maintenance. A simple wash with soap and water is typically all that’s needed. A pressure washer can be used cautiously, but avoid prolonged exposure to high pressure in one area.

- Aluminum Siding: Aluminum siding is easy to clean, often requiring only a hose-down. For more persistent stains, a mild detergent solution can be used. Avoid abrasive cleaners that can scratch the surface.

Repairing Damaged Siding

Damage can occur from various sources, including weather events, impact, or age. Knowing how to address these issues promptly can save you significant costs in the long run.

- Vinyl Siding: Minor cracks or dents in vinyl siding can often be repaired with a vinyl siding repair kit. Larger sections may require replacement. Remember to match the color and texture as closely as possible.

- Wood Siding: Repairing wood siding often involves replacing damaged boards. Rotted areas need to be cut out and replaced with new, treated lumber. Proper caulking is crucial to prevent water intrusion.

- Fiber Cement Siding: Repairing fiber cement siding usually involves patching or replacing damaged sections. Special fiber cement patching compounds are available to blend seamlessly with existing siding. Always wear appropriate safety gear when working with fiber cement, as it can release harmful dust.

- Aluminum Siding: Aluminum siding is relatively durable but can be dented. Minor dents can sometimes be pushed out from the back. Significant damage often requires replacement panels.

Preventing Common Siding Problems

Proactive measures are key to minimizing maintenance and repair needs.

- Regular Inspections: Conduct regular inspections (at least twice a year) to identify and address small problems before they escalate. This includes checking for cracks, loose panels, signs of rot or insect infestation, and damaged caulking.

- Proper Caulking: Regularly inspect and replace caulking around windows, doors, and other areas where siding meets other building materials. Proper caulking prevents water intrusion, a major cause of siding damage.

- Gutter Maintenance: Ensure your gutters are clean and functioning correctly to prevent water damage to your siding. Clogged gutters can cause water to overflow and run down the siding.

- Tree Trimming: Keep trees and shrubs trimmed away from your siding to prevent damage from branches and to improve airflow, which helps prevent moisture buildup.

Case Studies

Real-world applications offer invaluable insights into the performance and suitability of different siding materials. Examining successful projects across diverse climates and architectural styles reveals practical implications often overlooked in theoretical discussions. By analyzing these case studies, we can gain a deeper understanding of the factors influencing material selection and the long-term outcomes associated with each choice.

The following examples highlight the successful implementation of various siding materials in different contexts. We’ll look at the building type, location, climate considerations, and the ultimate success or challenges faced. This analysis provides a practical framework for informed decision-making in your own siding projects.

Case Study Examples: Siding Material Performance in Diverse Settings

The table below summarizes key characteristics of several buildings, showcasing the practical application of different siding materials. Note that “Outcome” refers to the observed performance, including longevity, maintenance needs, and overall aesthetic appeal.

| Building Type | Location | Siding Material | Outcome |

|---|---|---|---|

| Modern Farmhouse | Coastal Maine, USA (High humidity, strong winds) | Cedar Clapboard | Excellent weather resistance; required regular sealing; aesthetically pleasing, maintained its charm for over 15 years. |

| Victorian-Style Home | Denver, Colorado, USA (Dry climate, significant temperature fluctuations) | Fiber Cement Siding | Low maintenance; excellent durability against temperature extremes; consistent color retention; minimal repairs needed after 20 years. |

| Contemporary Apartment Building | Miami, Florida, USA (High humidity, intense sun exposure) | Aluminum Siding | Resistant to moisture and insect damage; required repainting after 10 years due to sun fading; relatively low maintenance overall. |

| Traditional Ranch House | Phoenix, Arizona, USA (Extreme heat, low humidity) | Stucco | Excellent heat resistance; required minor repairs due to cracking after 15 years, likely due to ground movement; generally low maintenance. |

Closure

Ultimately, selecting the ideal siding material involves careful consideration of numerous factors, from initial cost and aesthetic appeal to long-term maintenance and environmental impact. By weighing the advantages and disadvantages of each option – as Artikeld in this comprehensive comparison – you can confidently choose a siding solution that enhances your home’s value, beauty, and sustainability. Remember, the right siding is an investment that pays off for years to come.

So, do your research, weigh your options, and choose wisely!