Green Insulated Siding A Complete Guide

Green Insulated Siding A Complete Guide – Green Insulated Siding: A Complete Guide. Choosing sustainable building materials is no longer a niche pursuit; it’s a smart, forward-thinking strategy. This guide dives deep into the world of eco-friendly siding, exploring everything from the environmental benefits and diverse material options to installation techniques, cost-effectiveness, and long-term sustainability. We’ll uncover how you can drastically reduce your home’s carbon footprint while enhancing its energy efficiency and curb appeal – all without breaking the bank.

Get ready to transform your home and your impact on the planet.

We’ll examine various types of green insulated siding, comparing their performance, cost, and lifespan. You’ll discover how the manufacturing processes contribute to their environmental credentials, and learn practical installation tips and maintenance strategies to ensure your siding performs optimally for years to come. Finally, we’ll explore the financial incentives and long-term cost savings associated with choosing green insulated siding, empowering you to make an informed decision for your home and the environment.

Types of Green Insulated Siding

Choosing the right green insulated siding is a crucial decision impacting both your home’s aesthetic appeal and its environmental footprint. The market offers a variety of options, each with unique characteristics concerning material composition, insulation properties, cost, and longevity. Understanding these differences is key to making an informed choice that aligns with your budget and sustainability goals.

Green Insulated Siding Material Comparison

The selection of green insulated siding extends beyond simply choosing a material; it involves considering the entire lifecycle, from manufacturing to disposal. Below is a comparison of four popular types, highlighting their key features.

| Siding Type | Material Composition | R-Value (Approximate) | Cost (per sq ft, approximate) | Lifespan (Years) |

|---|---|---|---|---|

| Fiber Cement Siding with Foam Insulation | Cement, cellulose fibers, foam insulation core (polyisocyanurate or polyurethane) | R-7 to R-10 | $4-$8 | 50+ |

| Recycled Plastic Composite Siding | Recycled plastics, wood fibers, and other additives | R-5 to R-8 | $3-$6 | 30-50 |

| Wood Fiber Cement Siding | Cement, wood fibers, and additives | R-4 to R-6 (depending on thickness) | $3-$7 | 30-50 |

| Insulated Vinyl Siding | Polyvinyl chloride (PVC) with foam insulation core (polyurethane or polystyrene) | R-5 to R-8 | $2-$5 | 20-30 |

Note: R-values and costs are estimates and can vary based on manufacturer, thickness, and regional factors. Lifespan estimates assume proper installation and maintenance.

Manufacturing Processes and Sustainable Practices

Sustainable practices are integral to the production of environmentally conscious siding. Fiber cement siding, for instance, often incorporates recycled materials in its composition, reducing reliance on virgin resources. Manufacturers may also utilize energy-efficient production processes and implement waste reduction strategies to minimize their environmental impact. Recycled plastic composite siding directly addresses plastic waste, diverting it from landfills and transforming it into a durable building material.

The use of reclaimed wood fibers in some wood fiber cement sidings further contributes to responsible resource management. Even in the production of insulated vinyl siding, some manufacturers are exploring the use of recycled PVC and adopting environmentally friendly manufacturing techniques. However, it is crucial to examine each manufacturer’s specific sustainability claims and certifications.

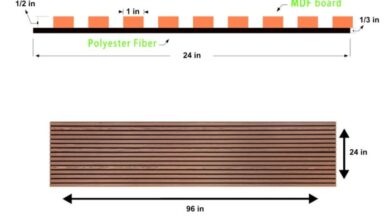

Installation Process: Fiber Cement Siding with Foam Insulation

Visualizing the installation process helps in understanding the overall project. Imagine a home’s exterior wall. First, a layer of moisture barrier is applied directly to the sheathing to prevent water intrusion. Then, the insulated fiber cement siding panels, each featuring a pre-attached foam insulation core, are precisely affixed to the wall using specialized fasteners. These fasteners are strategically placed to allow for expansion and contraction due to temperature fluctuations.

Each panel is carefully aligned to maintain a consistent and aesthetically pleasing look. The seams between panels are sealed with a high-quality sealant, creating a watertight barrier. Finally, any necessary trim pieces are installed to complete the installation. The result is a durable, energy-efficient, and visually appealing exterior wall system. This method reduces installation time compared to traditional siding and insulation applications.

Installation and Maintenance of Green Insulated Siding

Choosing and installing green insulated siding is a significant investment in your home’s energy efficiency and curb appeal. Proper installation ensures optimal performance and longevity, while regular maintenance prevents costly repairs down the line. This section will equip you with the knowledge and steps needed for a successful project, maximizing your return on investment and minimizing potential headaches.

Installation of Green Insulated Siding: A Step-by-Step Guide

Before you begin, meticulously plan your project. Accurate measurements are crucial to avoid material waste and ensure a seamless finish. This involves carefully assessing the existing wall structure, identifying any potential obstacles, and creating a detailed layout plan. Having a comprehensive plan will significantly reduce on-site issues and streamline the entire process.

- Preparation: Begin by thoroughly cleaning the existing wall surface. Remove any loose paint, debris, or old siding. Repair any damaged areas of the underlying wall structure, ensuring a smooth, even surface for the new siding. This foundational step is critical for a long-lasting and aesthetically pleasing installation.

- Framing and Sheathing (if necessary): Depending on your existing wall structure, you may need to install additional framing or sheathing to provide a suitable base for the insulated siding. This step is particularly important for older homes or those with uneven surfaces. Ensure proper alignment and secure fastening for a stable foundation.

- Installation of the First Course: Carefully install the first course of siding according to the manufacturer’s instructions. Pay close attention to alignment and ensure proper overlap. Using a level and plumb bob will guarantee a straight and professional-looking installation. Accurate installation of the first course sets the stage for the rest of the project.

- Installing Subsequent Courses: Continue installing subsequent courses, maintaining consistent alignment and overlap. Use appropriate fasteners, ensuring they are driven straight and flush with the surface. Regularly check your work for alignment and squareness to prevent problems further down the line. Consistent quality control throughout the installation is key.

- Finishing Touches: Once the siding is installed, install any necessary trim pieces, such as corner boards, J-channels, and window and door casings. These details add a polished finish and protect the edges of the siding. Attention to detail in this stage significantly enhances the overall aesthetic appeal.

- Inspection and Cleanup: After installation, conduct a thorough inspection to ensure all pieces are properly secured and aligned. Clean up any debris or leftover materials, leaving the work area tidy and presentable. This final step showcases professionalism and ensures homeowner satisfaction.

Necessary Tools and Safety Precautions

Appropriate tools and safety measures are paramount for a successful and safe installation. Investing in quality tools not only improves the efficiency of the work but also enhances the final product’s quality. Safety should always be prioritized to avoid accidents and injuries.

- Tools: Measuring tape, level, plumb bob, circular saw, utility knife, hammer, drill, safety glasses, work gloves, and appropriate fasteners.

- Safety Precautions: Wear appropriate personal protective equipment (PPE) including safety glasses, work gloves, and sturdy footwear. Use caution when operating power tools, following all manufacturer’s instructions. Always work on stable scaffolding or ladders, ensuring secure footing at all times. Proper safety protocols minimize risks and ensure a safe working environment.

Maintenance of Green Insulated Siding, Green Insulated Siding A Complete Guide

Regular maintenance is crucial for preserving the performance and appearance of your green insulated siding. A proactive approach can significantly extend the lifespan of your investment and prevent costly repairs. This section Artikels a simple yet effective maintenance plan.

Regularly inspect your siding for any signs of damage, such as cracks, loose fasteners, or discoloration. Address minor issues promptly to prevent them from escalating into larger problems. For example, a loose fastener can be easily tightened, preventing further damage to the siding.

Clean your siding at least once a year, using a mild detergent and water solution. Avoid using harsh chemicals or abrasive cleaners, which can damage the siding’s surface. For more stubborn stains, consider using a pressure washer, but maintain a safe distance to prevent damage. Regular cleaning keeps your siding looking its best and protects it from the elements.

Troubleshooting Common Installation Issues

Despite careful planning and execution, some issues may arise during installation. Knowing how to address these problems promptly can save time and resources. This section highlights common problems and their solutions.

Uneven Siding: If the siding is uneven, double-check the framing and sheathing for any inconsistencies. Ensure that the first course is perfectly level and plumb, as this sets the standard for the rest of the installation. Use shims to correct minor imperfections. Careful attention to detail during the initial stages of installation helps prevent uneven siding.

Gaps or Overlaps: Gaps or inconsistent overlaps can be caused by inaccurate measurements or improper installation. Carefully review the manufacturer’s instructions and ensure consistent overlap. Use appropriate trim pieces to cover minor gaps. Precise measurements and adherence to installation guidelines minimize gaps and overlaps.

Damaged Siding: Handle the siding carefully to prevent damage during installation. Replace any damaged pieces immediately. Using protective coverings during transport and installation protects the siding from scratches and other damage.

Cost and Energy Efficiency of Green Insulated Siding

Choosing the right siding for your home is a significant investment, impacting both your upfront costs and long-term energy bills. Green insulated siding, while often carrying a higher initial price tag compared to traditional options, offers substantial returns through improved energy efficiency and potential cost savings over the lifespan of your home. Let’s delve into the financial aspects of this eco-friendly choice.Green insulated siding typically costs more upfront than traditional vinyl or fiber cement siding.

Obtain access to Affordable Home Remodeling Ideas That Add Value to private resources that are additional.

This higher initial cost is attributable to several factors: the incorporation of insulating materials within the siding itself, often requiring more complex manufacturing processes; the specialized labor potentially needed for installation, given the often more intricate nature of the panels; and the generally higher material costs associated with environmentally friendly and durable components. A typical increase in initial cost can range from 20% to 50%, depending on the specific type of green insulated siding chosen and the size of the project.

However, this increased initial investment is often offset by significant long-term savings.

Initial Cost Comparison

To illustrate the initial cost difference, consider a hypothetical 1,500 square foot home. Traditional vinyl siding might cost approximately $8,000 to $12,000 for materials and installation, while green insulated siding could range from $12,000 to $18,000, reflecting a $4,000 to $6,000 difference. This variation stems from the differing material costs, and the potentially higher labor costs associated with the more complex installation process of insulated siding.

Remember that this is a broad estimate, and actual costs will vary based on location, contractor, and material choices.

Long-Term Cost Savings Through Energy Efficiency

The real value proposition of green insulated siding lies in its energy efficiency. By reducing heat transfer through the walls, it significantly lowers your heating and cooling costs. Let’s consider a practical example. Assume a homeowner experiences an average annual energy bill of $2,000 before installing green insulated siding. With the improved insulation, this could be reduced by 15% to 25%, depending on the climate and the R-value of the siding.

This translates to annual savings of $300 to $500. Over a 20-year period, this translates to a savings of $6,000 to $10,000. This easily offsets the higher initial cost in many cases, turning the initial investment into a long-term financial benefit.

The reduction in energy consumption directly translates to lower utility bills and a smaller carbon footprint.

Government Incentives and Rebates

Many governments offer financial incentives to homeowners who invest in energy-efficient upgrades, including siding. These incentives can significantly reduce the upfront cost of green insulated siding. These incentives can take various forms, such as tax credits, rebates, and low-interest loans. Homeowners should check with their local and state energy agencies to determine what programs are available in their area.

For example, some programs offer a percentage rebate based on the cost of the materials and installation, while others provide a fixed dollar amount per square foot of installed siding. Taking advantage of these incentives can further enhance the financial attractiveness of choosing green insulated siding. It is crucial to research these programs before starting your project to maximize your savings.

Environmental Impact and Sustainability

Choosing green insulated siding isn’t just about aesthetics and energy efficiency; it’s a significant decision with far-reaching environmental implications. Understanding the lifecycle impact – from manufacturing to disposal – is crucial for making an informed choice that aligns with sustainability goals. This section delves into the environmental footprint of various green siding options, comparing them to traditional materials and examining their recyclability and biodegradability.Manufacturing processes, transportation distances, and the embodied energy of raw materials all contribute to the overall environmental impact of green insulated siding.

Different materials possess varying degrees of sustainability, influenced by factors such as the sourcing of raw materials, manufacturing energy consumption, and the potential for recycling or reuse at the end of the product’s life.

Manufacturing and Disposal Impacts of Green Insulated Siding

The environmental impact of manufacturing green insulated siding varies significantly depending on the specific material used. For instance, fiber cement siding, while often considered a sustainable option, requires energy-intensive manufacturing processes. The production of cement itself is a significant carbon emitter. Conversely, recycled plastic siding offers a lower carbon footprint due to the utilization of pre-existing materials, thereby reducing the demand for virgin resources.

The disposal of these materials also presents different challenges. Fiber cement siding is often landfilled, while some recycled plastic siding can be processed and reused. The disposal methods impact the long-term environmental burden of each option. Proper disposal practices, such as recycling or responsible landfilling, are vital to minimize the negative consequences.

Carbon Footprint Comparison: Green vs. Traditional Siding

A comprehensive lifecycle assessment is necessary to accurately compare the carbon footprint of green insulated siding with traditional options like vinyl or wood. While vinyl siding may initially seem inexpensive, its manufacturing process often involves the use of petroleum-based products and releases greenhouse gases. Wood siding, while a renewable resource, can have a substantial carbon footprint depending on the harvesting and transportation methods employed.

Studies have shown that certain types of green insulated siding, particularly those made from recycled materials or rapidly renewable resources, can significantly reduce the carbon footprint compared to these conventional alternatives. For example, a life cycle assessment might show that a siding made from recycled plastic has a 30% lower carbon footprint than vinyl siding, primarily due to reduced energy consumption and reliance on virgin materials.

Recyclability and Biodegradability of Green Insulated Siding Materials

The recyclability and biodegradability of green insulated siding materials are key factors in determining their overall environmental sustainability. Some materials, such as certain types of recycled plastic siding, are more readily recyclable than others. However, the recycling infrastructure for these materials may not be universally available, limiting their practical recyclability. Other green options, like wood siding from sustainably managed forests, offer the potential for biodegradation, though this process can take considerable time.

Conversely, materials like fiber cement siding typically end up in landfills, resulting in long-term environmental concerns. Understanding the end-of-life management options for each type of green insulated siding is crucial in assessing its long-term sustainability. For example, a study by the EPA on the recyclability of building materials may show that only a small percentage of fiber cement siding is currently recycled, highlighting the need for improved infrastructure and consumer awareness.

Choosing the Right Green Insulated Siding: Green Insulated Siding A Complete Guide

Selecting the ideal green insulated siding involves careful consideration of several key factors. The right choice will not only enhance your home’s aesthetic appeal but also significantly impact its energy efficiency, longevity, and environmental footprint. This section will guide you through the decision-making process, helping you make an informed choice that perfectly suits your needs and budget.

Decision-Making Flowchart for Green Insulated Siding Selection

A strategic approach to selecting green insulated siding is crucial. The following flowchart simplifies the process, guiding you through key considerations based on your budget, climate, and desired aesthetic. Remember, this is a guideline; professional consultation is always recommended for complex scenarios.

Factors to Consider When Choosing a Contractor

Selecting the right contractor is paramount to a successful installation. A poorly executed installation can negate the benefits of even the highest-quality green insulated siding.

Prioritize contractors with demonstrable experience in installing green insulated siding. Look for evidence of successful projects similar in scope and complexity to your own. Check online reviews and testimonials from previous clients to gauge their level of satisfaction. Verify that the contractor holds all necessary licenses and insurance, ensuring both legal compliance and protection in case of unforeseen issues.

Request detailed quotes that clearly Artikel the materials, labor costs, and project timeline. Finally, confirm that the contractor adheres to environmentally responsible practices throughout the installation process.

Examples of Successful Green Insulated Siding Installations

Successful installations showcase the versatility and adaptability of green insulated siding across diverse architectural styles and climates.

Imagine a charming Victorian home in a coastal New England town, clad in sustainably harvested cedar siding, its natural beauty enhanced by a weather-resistant, high-performance insulation system. The siding’s natural tones complement the home’s architectural details, creating a harmonious blend of traditional aesthetics and modern energy efficiency. Contrast this with a sleek, modern home in a sun-drenched Arizona desert landscape.

Here, a light-colored, highly reflective fiber cement siding with superior insulation properties keeps the interior cool, reducing energy consumption and minimizing the environmental impact of air conditioning. Each installation demonstrates how careful selection and skilled installation can enhance both the home’s visual appeal and its sustainability.

Final Conclusion

Ultimately, the decision to choose green insulated siding is an investment in a healthier planet and a more energy-efficient home. By understanding the diverse options available, the installation process, and the long-term benefits, you can confidently select the perfect siding to complement your architectural style, climate, and budget. Remember, it’s not just about aesthetics; it’s about building a sustainable future, one eco-friendly home at a time.

This guide provides the knowledge you need to make a truly impactful choice.